BAKELITE

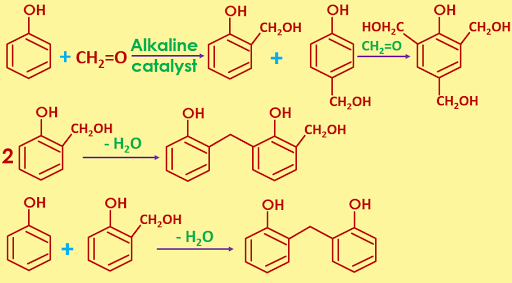

Phenolic resins are known as bakelite. The phenol formaldehyde resins are the oldest synthetic plastic. They may be made from almost any phenol body and an aldehyde by a process known as condensation polymerization. The initial reaction between the two, in presence of an alkaline catalyst, produces o and p hydroxy methyl phenol or o and p hydroxy benzyl alcohol. These initial products react among themselves with the formation of methylene bridges between two rings.

MANUFACTURE

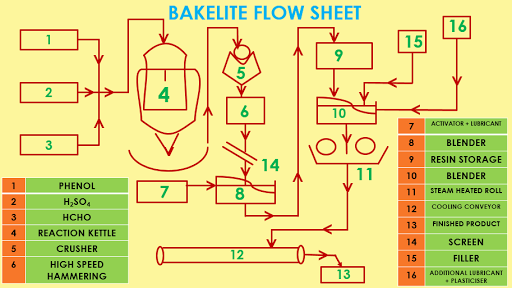

Ca(OH)2 (1-2 parts) along with phenol and formaldehyde (100 parts) with a formaldehyde to phenol ratio (1.1-1.5) are charged into the reaction kettle. The reaction takes place within few minutes at 930C - 1000C temperature, but takes about 2 or 3 hours at 650C - 750C. The reactions, however depends upon the total exchanged capacity of the reaction equipment,the concentration of the catalyst and the type of resin to be prepared. After the reaction is completed, the water is removed by distillation under reduced pressure at 700C - 720C . The catalyst is neutralised by adding a weak acid, such as lactic acid in hot solution. About (13-15) % glycerol is added to the solution, if transparent castings are required. The trace of water is removed by dehydration in vacuum at 750C - 850C. The product of the reaction is either moulded directly or converted into moulding powder. Moulding is carried out by passing the liquid resin into preheated moulds and allowed to cool slowly at 600C - 800C. Moulding powder is obtained by pouring the liquid resin into large steel floor under which cold water flows for uniform cooling of the mass. After cooling the resin is powdered and then blended with filters, colouring materials and mould releasing agents etc. The blended product is then fused on hot ball mills into moulding powder.

Bakelite set to rigid, hard, scratch resistant, in fusible, water resistance, insoluble solids, which are resistance to non-oxidising acids and many organic solvents. However, they are attacked by alkalies due to the presence of free hydroxyl groups in their structure. They have excellent electrical insulating character.

USES

Bakelite is used for making electrical materials, automobile parts, radio and T.V set bodies etc.

No comments:

Post a Comment